One-Stop Customization Service

From Concept to Launch · From Single Item to Full Category · Empowering Retail Growth

Before You Worry, We’ve Already Solved It.

Lack of stable new product sources

Creativity is difficult to quickly put into practice

Too many suppliers make SKU management costly

Delivery dely missing the sales golden period

Products & Solutions

OEM & ODM solutions for global brands Sustainable· Reliable · Efficient

Our Process

From design to delivery -a seamless, efficient workflow tailored for your brand.

ODM workflow

Concept Discussion

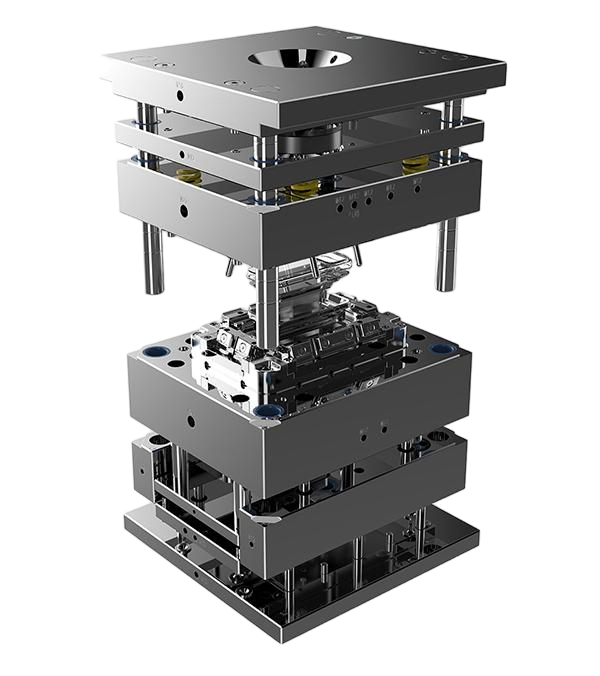

Design & Mold

Sample Approval

Production & Delivery

High-Tech Manufacturing Process

Tolerance range

±0.01mm

High-precision mold technology offers an accuracy of ±0.01mm, ensuring the phone case fits the device perfectly (100%) and supports various applications like outdoor mount setups, waterproofing, and drop protection.

Application

Shells for 3C electronic products

Precision medical devices

High-end equipment

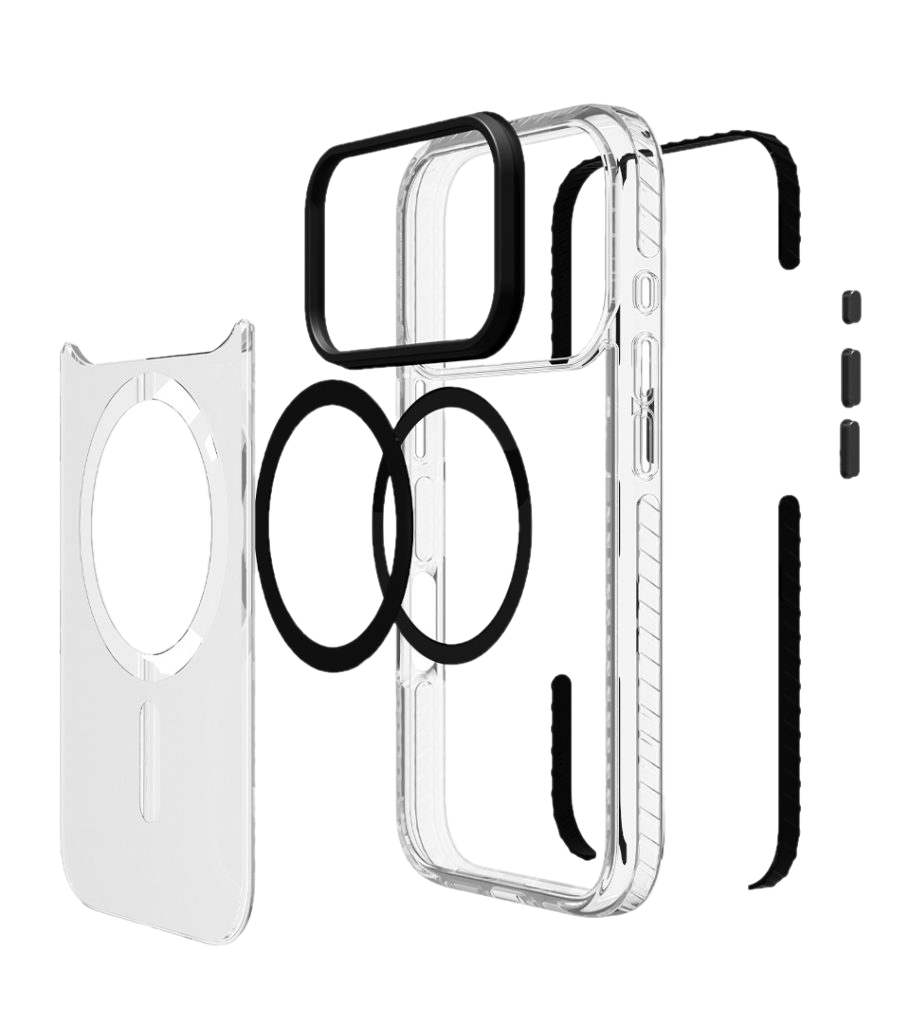

Multi-component injection molding

Overmolding

The multi-material molding process enables phone cases to be made from combinations like PC+TPU, TPU+TPE, TPU+silicone, or glass+silicone, effectively leveraging the unique benefits of each material.

UV printing

UV printing can apply different materials to the phone case, with the print layer raised by 2–3mm to create unique textures. For heights over 3mm, please consult with our engineers.

Laser Engraving

Laser cutting is often the ideal method for creating patterns on metal and textured leather, as it enhances the material’s natural texture.

Pad Printing

Pad printing works well on uneven surfaces, as the ink conforms to the texture and forms a clear, complete pattern. This method is especially effective on biodegradable materials.

Thermal transfer

For vibrant and detailed color effects, thermal transfer is an excellent option. It can deliver visuals on certain materials that resemble the clarity and brightness of an LED screen.

The edges are hand-polished and coated with edge paint for a smooth, seamless finish that prevents peeling and enhances the premium look.

Every finished product passes metal detection to ensure safety and meet international quality standards.

Precise stitching ensures strong structure and clean lines. Each phone case is carefully sewn for durability and refined appearance.

Effects That Can Be Achieved

From materials and textures to colors patterns and custom molds every detail can be tailored to elevate your iPhone case. Add your own design or logo and explore full wrap around printing to create a truly personalized and standout product.

Color-Plated

Add a colorful electroplated finish to the metal back of the phone case.

Digital Printing

Print the image on the phone case’s back using RGB or CMYK methods.

Electroplating

Create an electroplating finish on the rear sheet of the phone case.

Gold Foil

Create a hot stamping finish on the back sheet of the phone case.

Silk Printing

Print designs onto the flat parts of the phone case using silk printing technology.

With Diamond

Add diamonds to the phone case for a luxurious touch.

With Glitter

Enhance your phone case with glitter for a sparkling finish.

IMD

Use CMYK printing to achieve colorful and intricate graphics on the phone case.

Green Partnership

Empowering your brand to grow responsibility-greener products, stronger trust.

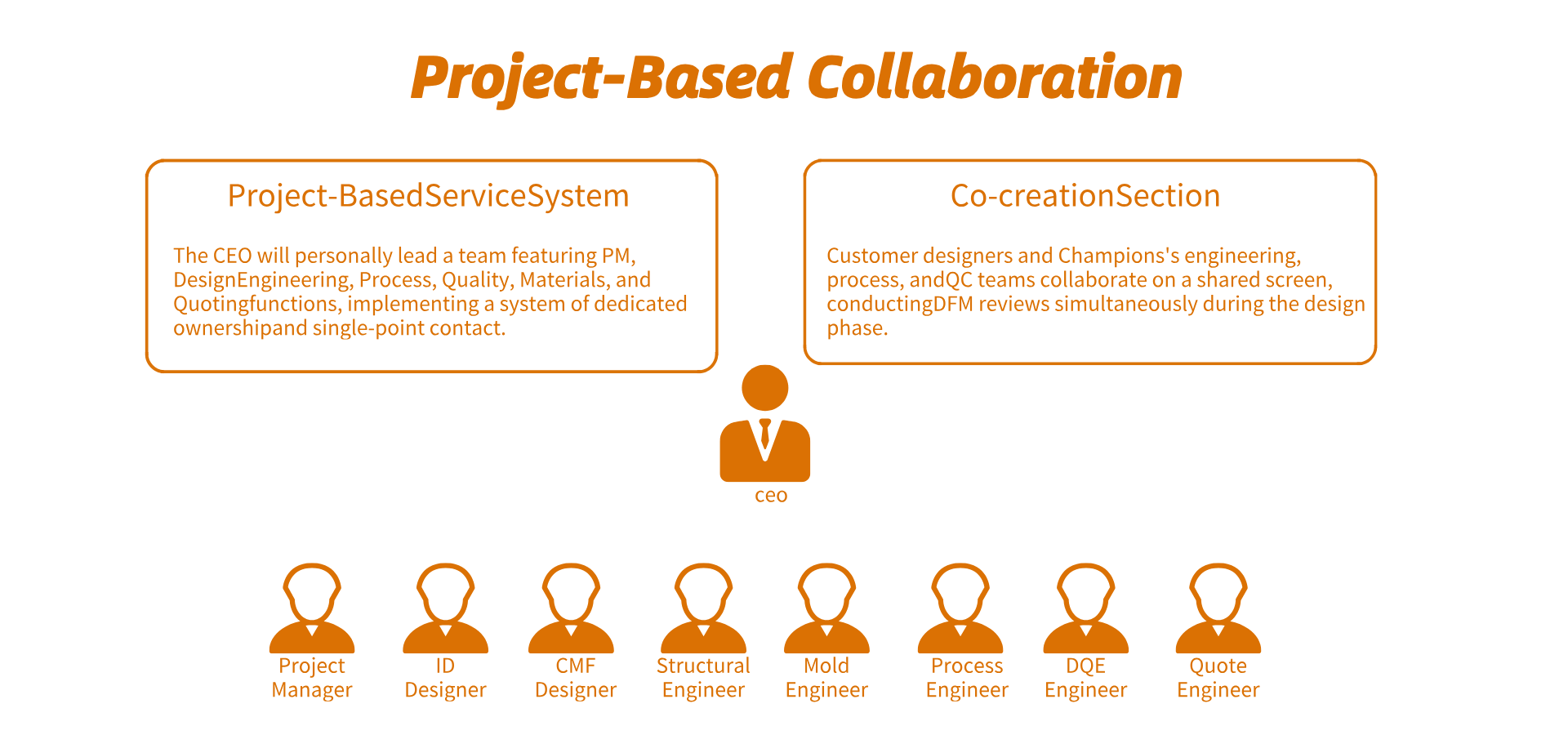

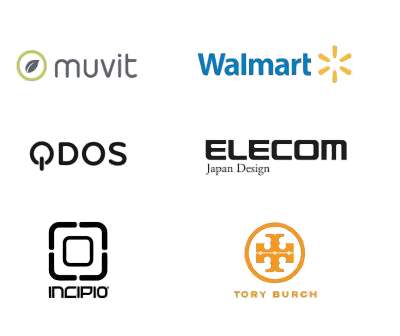

Cooperation Brand

About Us

10 Long Years Of Manufacturing Excellence With Quality At It's Best!

Guangzhou Champion’s Tech. Ltd., established in 2015 and situated in Guangzhou City, operates with a mission encapsulated in our slogan: “Anticipate the customer’s needs, deliver the unexpected excellence. ” Occupying an expansive independent facility spanning 12, 000 square meters, our daily production capacity reaches an impressive 80, 000 units. Specializing in the manufacturing of diverse mobile phone cases crafted from materials like TPU, PC, silicone, and more, we pride ourselves on being a leading force in the industry.

Behind our success lies a robust and skilled Research and Development team, tirelessly creating new products every month. Moreover, we offer assistance to clients in developing proprietary molds, supporting both OEM and ODM services. Our capabilities extend to providing color printing, IMD customization, laser engraving, and various other processes to cater to our clients’ unique requirements.

At Champion’s factory, we prioritize quality as an integral part of our corporate culture. Every stage of production undergoes stringent control measures to ensure impeccable results. Our commitment to excellence has propelled our products to be exported to over 80 countries and regions globally, including the United States, Britain, Germany, Japan, France, among others.

We take pride in our dedication to providing swift responses, reliable services, top-notch products, and expedited delivery. We eagerly anticipate the opportunity to collaborate with you, contributing to the success of your ventures.

Sed non mauris vitae erat consequat auctor eu in elit. Class aptent taciti sociosqu ad litora torquent per conubia nostra, per inceptos himenaeos. Mauris in erat justo.

Our Products

We are the industry heads and produce the most reliable and trendy solution you are looking for.

What is the minimum order quantity (MOQ)?

Typically, our MOQ is 100 pieces per design. For basic designs, we can support low MOQ to help you test the market. Please contact us for detailed information.

How long is the production time?

For orders of 1–1000 pieces, the production time is typically 5–15 working days depending on the complexity. For quantities over 1000 pieces, the delivery time can be negotiated. We also offer priority production for urgent or high-volume orders.

Can I customize the packaging?

Yes, we offer full packaging customization options including logo printing, box design. Our team can help you create packaging that matches your brand image.